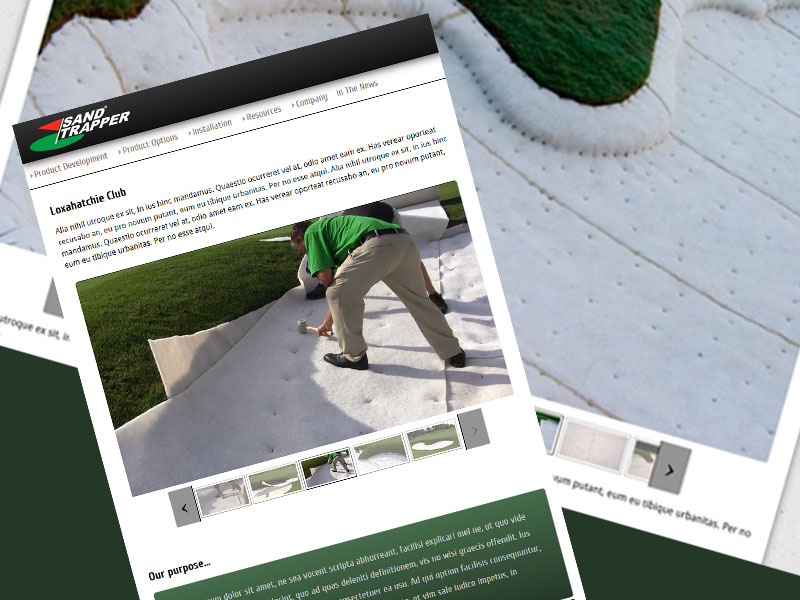

Installing Sandtrapper Bunker Liners is a straightforward, intuitive process. There are just a few basic guidelines that should be followed to have successful project. Over time, we've seen many different methods for installing Sandtrapper. Each method is driven by bunker design/style, topography, local climate, soil conditions, and individual preference. What we showcase here are several of the more common techniques.

It is important to state that every golf course is a unique product, with its own set of circumstances. Each bunker project will have its own solutions and considerations. A golf course should always seek the advice of trusted professionals, architects, and builders before proceeding with a project.

Some facilities may already have accurate bunker measurements from original course designs or past estimating. It is always a good idea to double check measurements where possible. For simple bunker designs, the simplest method for determining area is to take two measurements on the ‘X’ and ‘Y’ axes. Slightly more accurate is to divide the bunker into four quarters and measure each quarter separately.

For simple bunker designs is recommended to add 10% to the base measurement. For moderate bunker designs, 13 to 15% should be added. For more drastic or complex designs, 18 to 20% should be added. Should you require additional product during the project, IVI-GOLF can get additional quanities moving quickly so delays are avoided.

More detailed information here.

When renovating golf course bunkers, it’s the perfect time to consider any improvements in design, playability, and functionality. Most importantly, drainage should be assessed to determine water flow out of the bunker and correct poor designs.

Prior to installing Sandtrapper, existing sand should be cored from the bunker and reserved for other uses around the course. Once sand is removed, it is a good time to adjust or reshape the base of the bunker and/or prepare for any drainage work that may be performed. The bunker base should be firm and compacted prior to the installation of the liner.

With the sand removed, it’s also recommended to address the cut or edge of the bunker. Like the base, the cut should be firm and compact. On bunkers with a higher degree of slope, it’s recommended to have a small “shelf” at the base of the cut. Some facilities will even go so far as to excavate a small groove into the base of the cut.

More detailed information here.

If a bunker has existing drainage, the bunker drainage system should be checked, cleaned, and/or repared prior to installing Sandtrapper. Design varies widely, from simple ‘Y’ designs, to herringbone or “French” drainage systems. It is also common to see smile drains incorporated into drainage systems and used across slopes to pull water more quickly. Any drainage line that is placed should be perpendicular to the slope of the bunker.

More detailed information here.

There are two basic theories concerning how best to arrange Sandtrapper in a bunker. For most, the objective is to minimize seams and to use as many continuous segments as possible. For others, the focus is on minimizing product waste. There are a number of trade-offs to consider when organizing for product placement.

For those looking to have the fewest seams possible, the 90” roll width helps to acheive this objective. The wider roll widths speed installation (reduced cutting and stapling time/cost) but will lead to an increase in product waste.

For those looking to reduce material waste, this can be acheived by using the 56” roll width and by incorporating smaller segments where they will fit. Since Sandtrapper is a non-woven material, there is no orientation that you need to match from one segment to another.

More detailed information here.

We recommend that seams between Sandtrapper segments be overlapped 2”-3” so that the securing sod staple will be driven through both segments. Increasing the overlap is acceptable and does not change performance. With regards to overlap, some prefer to place Sandtrapper much the way one would shingle a roof, with the bottom segment at the base and working upwards.

In order to better secure Sandtrapper, it is recommended that placing seams directly over drainage lines be avoided. This applies specifically to cases where Santrapper is alligned parallel to the main drain line. It’s recommened that you position Sandtrapper over the drain line so that there is adequate area to secure the liner onto either side of the drainage trench.

More detailed information here.

IVI-GOLF offers a range of fastener products that can be used to secure Sandtrapper to the bunker substrate. Although the most common is the 8-inch, 11 gauge sod staple, IVI-GOLF carries a wide range of dimensions, gauges, and styles to suit specific installation requirements.

The most common estimate we see used is one staple per square foot. When bunkers have steeper slopes, the density needs to be increased to 1.5 staples per square foot. The normal routine for staple use is one staple every 6 to 8 inches along seams and edges and every 12 to 15 inches in the interior. This pattern will vary based on your location in the bunker. Sloped faces will require the field pattern to be tighter. Bunker bases afford the use of fewer staples, spread farther apart. As a general rule, it’s recommended to drive staples into the soil at a slight angle. This allows for a better attachment and helps prevent heaving in northern climates.

More detailed information here.

Much will depend on the shape/design of the bunker and the soil conditions present. It will also depend on the preferences of the course/superintendent as to how they would implement bunker liner technology. It is important to address edges securely. If staples are spaced more narrowly, you will insure a better, more secure install.

Most installations will cover the completed, graveled drainage trenches for a complete coverage of the bunker with the liner. This eliminates any concern over contamination. Some courses/superintendents will prefer to have access to drainage lines.

A variety of methods exist to install Sandtrapper at the bunker edges. Each has it’s own advantage, given soil types and grass varieties. OPTION A - Sandtrapper is brought to and up the bunker edge, being secured into the edge with sod staples. OPTION B - Sandtrapper is brought to and up the bunker edge, then tucked into the soil below the root zone of the grass above. OPTION C - Sandtrapper is brought up and over the bunker edge. Grass is placed on top with root structure growing into the liner. OPTION D - Super Mighty Edge is applied under the liner and secured into the edge with sod staples for long-term bunker protection.

More detailed information here.

Over the years, we’ve seen a number of innovative methods to install Sandtrapper. They address particular issues in creative ways to address specific needs of the course.

Staple Topping - In northern climates where the freeze-thaw cycle is a concern, some superintendents have used construction adhesive to secure the top of the sod staple to the bunker liner. Applying a small dab of adhesive on the staple top and spreading/smoothing to the liner increases the surface area in contact with the liner. The result is a significant reduction of heaved staples when frequent freeze/thaw cycles occur during the winter months.

Seam Butting - Some facilities prefer not to overlap seams. Instead, we’ve seen where the edges of Sandtrapper are butted together and set with a bead of contstruction adhesive.

Anchors & Washers - Some rocky soil conditions make it extremely difficult to secure Sandtrapper with sod staples. In these situations, we’ve seen facilities place a steel/spike and washer through the liner and hammer into the rocky soil. In situations where the subsurface is entirely bedrock, we’ve seen facilities tap pilot holes with masonry bits and drive masonry anchoers (with washers) to secure the liner.

More detailed information here.

Sandtrapper II - (PDF)

Sandtrapper MD - (PDF)

Sandtrapper I - (PDF)

Sandtrapper SL - (PDF)

Geotextile-JM Evalith - (PDF)

Product Comparision Sheet (PDF)

Bunker Preparation (PDF)

Drainage Planning (PDF)

Product Allignment (PDF)

Edge Detail (PDF)

Product Estimating (PDF)

Fasteners (PDF)

Enhanced Techniques (PDF)

Images here

Video here

US Toll Free Telephone

(888) 970-5111

Contact Form here

©2016 IVI-GOLF. SANDTRAPPER IS A REGESTERED TRADEMARK OF INDIAN VALLEY INDUSTRIES, INC.. All Rights Reserved.